FIRST-M Consulting Ltd.

Failure Investigation

Infrastructure Reliability & Safety

Science & Technology of Materials

From Science to Solutions: Corrosion and Metallurgical Consulting Services

ADVANCES IN ENGINEERING & TECHNOLOGY

MAJOR TECHNICAL ADVANCES FROM THE WORK OF SHIPILOV AND COLLABORATORS

Summary: Research has been focused on preventing in-service failures in complex engineering systems, especially those that could potentially lead to disasters and environmental contamination, including nuclear power systems and oil and gas pipelines. Special attention has been paid to military equipment, including aircraft, submarines, and light armored combat vehicles. Investigated materials included high-strength low-alloy steels, stainless steels, carbon steels, cast irons, and titanium, aluminum, magnesium, and nickel-based alloys. Research findings have been used in aerospace, nuclear, naval, military, pipeline, medical devices, oil and gas, petrochemical, and infrastructure applications.

Highlight: In 2016, was initiated and eventually completed the most significant and only-ever successful research project on corrosion in the U.S. Armed Forces. Without Shipilov’s experience and expertise, the U.S. Army double V-hull (DVH) Stryker light armored vehicles (LAVs) and Canadian Army LAVs 6.0—also built on the DVH platform—would most likely still be sensitive to structural cracking on the lower-right fender, like it was in Afghanistan in the early-mid-2010s, meaning the vehicles could not be (actively) used in combat operations. If he failed like many others before him to solve the life-threatening problem and the DVH platform would not be upgraded after his research to the DVHA1 configuration, Canada’s government and the Biden administration would not be able in 2022 and early 2023 to send 39 LAVs and 90 Strykers to Ukraine to help the Ukrainian Armed Forces defend the country’s sovereignty, freedom, and independence. It is not apparent that Canada’s Department of National Defence and the U.S. Department of Defense would place at General Dynamics Land Systems-Canada contracts for $3 billion (CAD) and $2.48 billion (USD) in 2019 and 2020 to produce 1000+ new vehicles (each costing $4.9 million U.S.) if the life-threatening defect still existed.

Innovative R&D in Areas Critical in Importance for the Energy Sector and Defense:

-

While at Oak Ridge National Laboratory (2015-2017), Shipilov designed an experimental irradiation assembly (EIA) and associated remote-sensing instrumentation to conduct the world’s most challenging and demanding experiments in metallurgy/materials science and corrosion. The EIA allows for the first time in situ and operando monitoring of electrochemically controlled irradiation-assisted stress corrosion cracking (IASCC) in cyclically loaded fracture-mechanics specimens under the simultaneous influence of high-temperature water (up to 347 °C, 15.5 MPa) and intense radiation in the U.S. Department of Energy’s (DoE) High Flux Isotope Reactor (HFIR). Notably, HFIR provides one of the highest steady-state neutron fluxes of any research reactor in the world and the highest thermal neutron flux density of any reactor operating today in the Western world. It is essential that during the experiment, tensile test specimens—while located 46 cm from the center of the reactor core and exposed to an average thermal (neutron energy < 0.4 eV) neutron flux of 4.3E+14 n/cm^2·s and an average fast (neutron energy > 0.183 MeV) neutron flux of 1.2E+13 n/cm^2·s over 24 effective full power (85 MWt) days of irradiation—can be charged with hydrogen at any specific crack growth rate, measured in situ with the world’s highest average crack extension resolution of about 10 nm, allowing use—for the first time in high-temperature water—an experimental (electrochemical) method developed for quantitatively defining the extent of hydrogen-induced cracking (HIC) and stress-assisted dissolution in stress- corrosion cracking (SCC) and corrosion-fatigue crack growth (FCG).

-

Note: Over the last three decades, IASCC has become a potentially critical phenomenon for heavily irradiated core components in water-cooled nuclear reactors. IASCC has caused or extended outages at dozens of nuclear power plants worldwide, has required expensive repairs and reactor modifications, and has contributed to significant personnel radiation exposure. Reactor shutdowns because of the occurrence of IASCC and the remedies for damage caused severe economic disadvantages and difficulties in obtaining public acceptance for utilizing nuclear energy. According to the DoE, “IASCC is the highest interest in extended life scenarios” of all 90+ commercial nuclear reactors that generate nearly 20% of the electricity consumed in the United States.

-

With the experimental setup, it is now possible to evaluate the dose-dependent susceptibility to IASCC and make a residual-life assessment of reactor core components in aging water-cooled reactors at commercial nuclear power plants and nuclear-powered aircraft carriers and submarines in service with the U.S. and Allied navies, including seven Ohio-class ballistic missile submarines that operate well beyond their stated design limits.

-

In addition, the setup could be used to determine the long-term cracking resistance of core-component alloys and weldments, which are employed in the next-generation naval reactors and (would be) selected/designed for use in Generation III nuclear reactors under construction in the U.S. and elsewhere worldwide, Generation IV nuclear reactors, being developed through international cooperation of 14 countries (including Canada, China, Russia, and the United States), and high-level nuclear waste containers.

-

Previously, over the last two or three decades, several large organizations, including well-funded university research centers in the United States and DoE’s National Laboratories such as Argonne National Laboratory, Idaho National Laboratory, Oak Ridge National Laboratory, and Pacific Northwest National Laboratory—each manages a multi-billion dollar science and technology portfolio—tried to initiate the IASCC studies but were unable to develop a critical experiment, design a piece of experimental equipment, or produce valuable or at least helpful information on the in-core IASCC behavior of any group of materials under simulated or actual in-service conditions. The lack of a properly designed (critical) experiment and test facility did not allow the Cooperative IASCC Research (CIR) program—an international research effort that was established “to address IASCC in light water reactor components” and sponsored by member organizations from 10 countries since 1995—to achieve its goals “to develop a mechanistic understanding of IASCC, derive a predictive model of IASCC based on a mechanistic understanding, and thus to identify possible countermeasures to IASCC” after spending countless millions of dollars.

-

The innovative experimental setup was a Finalist for the 2021 MP (Materials Performance) Corrosion Innovation of the Year Award.

-

High Flux Isotope Reactor (HFIR) undergoing a defueling operation in July 2015. Photo: ORNL.

Schematic concept of the experimental irradiation

assembly for in-reactor IAFCC and IASCC tests in HFIR.

-

At the request of the U.S. Army Stryker Brigade Combat Team (SBCT), Shipilov determined the cause and mechanism of structural cracking on the lower-right fender of double V-hull (DVH) Stryker armored vehicles. In the early/mid-2010s, the problem questioned the ability of newer DVH vehicles to withstand blast mines and improvised explosive devices; it affected the availability of field vehicles in Afghanistan. The research won him the Best Paper Award at the 2017 DoD-Allied Nations Technical Corrosion Conference, sponsored by the Office of the U.S. Secretary of Defense, and the 2023 Oladis Troconis de Rincón Field Applied Technology Award of the Association for Materials Protection and Performance (AMPP). The research enhanced the blast protection of soldiers inside vehicles allowing the U.S. Army to announce contracts to produce 742 more DVH vehicles (each costing $5.4 million in 2019 dollars) between 2019 and 2021. In 2020, the U.S. Department of the Army decided that the 19-ton eight-wheel-drive armored DVH Stryker vehicle “will be the future backbone of 8 U.S. Army and 1 National Guard medium armored brigades.” As early as 2016, it was "thought the Stryker will bolster NATO forces [in Europe] that are not well equipped to counter the Russian threat" (D. Perry, 2016). In 2022, Canada’s government provided war-torn Ukraine with 39 armored combat support vehicles (ACSVs) built on the same platform as U.S. Army’s DVH Stryker; these 39 ACSVs were part of the government's $3 billion contract to produce 360 DVH vehicles for the Canadian Armed Forces.

-

Note: The DVH—manufactured by General Dynamics Land Systems-Canada (GDLS-C) in London, Ontario—was designed in response to high landmine-related casualties in Afghanistan. The design was supposed to provide infantrymen with enhanced protection and survivability from artillery fragments, roadside mines, and improvised explosive devices on the battlefield. Despite all the best intentions, after being put into use, the vehicles experienced structural cracking, which became a severe life-threatening problem that required immediate attention.

-

Before Shipilov’s involvement, GDLS-US, “a global leader in designing, engineering, producing, supporting and sustaining tracked and wheeled military equipment,” and Oak Ridge National Laboratory (ORNL), “the U.S. Department of Energy’s largest science and energy laboratory with over 4,600 staff” and “home to the nation’s most comprehensive materials research program”—each manages a multi-billion-dollar science and technology portfolio—failed to complete the investigations and help the U.S. Army to have a reliable Stryker vehicle capable of protecting soldiers’ lives.

-

The U.S. Army Stryker DVH vehicle. Photo: U.S. Army.

Materials Selection and Design:

-

Demonstrated that the microstructure of high-strength low-alloy steels of the same strength produces significant differences in SCC and corrosion FCG. This led to the discovery and proposal of new heat treatment methods and alloying additives that improved the crack growth resistance of high-strength steels used in aerospace and naval applications.

-

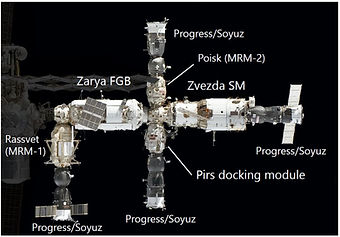

Developed (as a team member) and studied lightweight and highly resistant to cracking advanced structural materials for high-risk and safety-critical applications, including highly resistant to (internal) hydrogen-assisted cracking aluminum alloys (with a team of the Central Research Institute of Materials Science, Russia’s leader in the development of advanced materials for aerospace applications) for the space station Mir, which spent 15 years in orbit instead of the planned five, the Russian orbital segment of the International Space Station (including three main pressurized modules Zaria, Zvezda, and Nauka and docking compartment/module Pirs), and the upgraded Progress M cargo spacecraft which the purpose is to deliver the supplies needed to sustain a human presence in orbit.

-

Note: Previously, several large and well-funded research organizations responsible for R&D, testing, and certification of all materials used in the Soviet aerospace industry—including the All-Union Institute of Aviation Materials (VIAM), the All-Union Institute of Light Alloys (VILS), the Central Research Institute of Materials Science (now NPO “Komposit”) at S.P. Korolev Rocket and Space Corporation "Energia"—tried but were unable to develop a critical experiment and design an experimental setup to conduct investigations allowing to create an aluminum alloy resistant to HIC.

-

These advanced aluminum alloys with high resistance to HIC under cyclic loading are still the only aluminum alloys of this type available today in the Russian space industry. At present, no research institution/team in Russia has unique and highly sensitive equipment (or a similar one) and is familiar with the experimental approach developed by Shipilov for this project in the mid-1980s. For this reason, no new investigations can be conducted in Russia (and overseas) to design similar or more unique/novel aluminum alloys.

-

The world's first modular space station Mir, one of the most significant scientific achievements of the Soviet Union, was assembled in orbit from 1986 to 1996. Over its lifetime, Mir hosted 125 cosmonauts and astronauts from 12 different nations. The station’s integrity was never jeopardized; no hull of the seven modules experienced cracking after years of service in the harsh environment of space.

-

The International Space Station (ISS) is recognized as “the most complex scientific and technological endeavor ever undertaken” and “the world’s most expensive single item ever constructed.” As of 2010, its total cost was $150 billion, including NASA’s budget of $58.7 billion, Russia’s $12 billion, Europe’s $5 billion, Japan’s $5 billion, and Canada’s $2 billion. As of October 2022, 263 individuals from 20 countries (including 161 astronauts from the United States, 56 from Russia, and nine from Canada) visited the ISS, many of them multiple times. As of October 2021, there have been 46 flights of Progress M to Mir and 82 to the ISS.

-

The Zarya (Russian for "dawn") Control Module kicked off the assembly of the ISS in 1998; the Zvezda ("star") Service Module, which docked with Zarya in 2000, provides station living quarters, life support systems, electrical power distribution, data processing systems, flight control systems, and propulsion systems. The Pirs ("pier") module, launched in 2001, provides the ISS with one docking port for Progress and Soyuz spacecraft and allows egress and ingress for spacewalks by cosmonauts. The modules were designed to operate for 15 years.

-

In late 2020 and early 2021, six hairline cracks were discovered in the Zvezda’s intermediate chamber, causing an ongoing air leak. Although the leakage posed no danger to the station and the crew, the crew was required to move to the U.S. Orbital Segment. As suggested by FIRST-M in October 2020, the cracks (most likely) have a fatigue nature and were caused by (internal hydrogen-assisted cracking and/or) cyclically repeated stresses generated by heating (121 °C) and cooling (-157 °C) cycles, acting on the aluminum-alloy structure much as pressurization cycles cause cracks in aircraft over time, rather than by “a micrometeorite impact” as officially announced. Cracks found on the ISS were repeatedly mentioned as a “fairly serious issue” in a U.S. House Science, Space, and Technology Committee hearing on “NASA’s Future in Low Earth Orbit: Considerations for ISS Extension and Transition” held by the Subcommittee on Space and Aeronautics on September 21, 2021.

-

“Aging of materials and structures of the ISS could lead to irreversible consequences, up to a disaster,” said Deputy Prime Minister of Russia for Defense and Space Industry Yuri Borisov in April 2021 regarding the cracks after the Russian president announced that Russia will withdraw from the ISS project late 2024 due to the growing number of breakdowns and metal fatigue in the hull of Zvezda module. However, in September 2022, it was announced that “Russia is likely to take part in International Space Station until 2028.” Without Russian modules, the ISS would become non-functional.

-

On July 29, 2021, after the Pirs module was detached from the ISS, the Nauka (Russian for "Science") Multipurpose Laboratory Module successfully docked to Zvezda’s nadir port making the first significant expansion of the Russian ISS segment in the last 11 years. Nauka was initially built as a backup for the Zarya module to be ready for launch in 2007. Its construction began in 1995; the hull of the Nauka module—pretty much identical to that of the Zarya—was built of the same aluminum alloys, which were studied by Shipilov and selected primarily based on his research on their cracking resistance.

-

The Zvezda service module is under construction at the Khrunichev State Research and Production Space Center in Moscow, 1997. Photo: NASA.

The ISS’ Russian Orbital Segment in Earth orbit. Photo: NASA.

-

Developed (as a team member) and studied a modified titanium alloy with two times higher KISCC and 45% higher KIC. (Note: The research project was initiated after intensive SCC was revealed in the titanium hulls of Project 705 Lira-class [NATO reporting name Alfa] nuclear-powered attack submarines that forced the early decommissioning of six submarines in service with the Soviet Navy between 1990 and 1992.) The modified alloy (and its variants) was used to design the new titanium-hulled submarines, including two nuclear-powered attack submarines of the Project 945A Kondor class (NATO reporting name Sierra II), the most expensive ever built among the world’s fleet of underwater warfare vessels.

-

Note: The pressure hull is the primary structural element of a submarine, designed to withstand the external hydrostatic pressure (without buckling and, more importantly, cracking) to protect the crew from extreme environmental conditions at depth and allow the ship to function. The hulls are also subjected to chemical and biological deterioration in marine environments, making materials selection especially critical to the submarine’s effective and safe functioning. Light and strong titanium hulls allow the Project 945A submarines to dive to depths of up to 520 m (1,700 ft), enhance their survivability, and have a low magnetic signature. The class has a smaller turning circle than any other modern submarine, with a speed (32 knots) and diving depth greater than any foreign counterparts with a top speed of 25 knots and a maximum operating depth of 240 m. Despite remarkable advantages in the diving depth and underwater speed, the high cost of titanium hulls limited the number of submarines built. The class was supplemented by the Project 971 Shchuka-B-class submarines, which—though they are not as fast as titanium-hulled submarines and could not dive that deep—were easier and cheaper to build.

-

Some results of the studies on materials for submarine hulls—only those not directly related to the project’s main tasks but representing the most recent breakthroughs in research on environment-induced cracking have been published in the open literature.

-

-

Researched SCC and corrosion FCG in advanced high-strength low-alloy steels developed by the Central Research Institute of Structural Materials “Prometey”—Russia’s leader in materials development for nuclear, naval, energy, and military applications—for pressure hulls of Project 971 Shchuka-B-class (NATO reporting name Akula) nuclear-powered attack submarines. Results allowed the selection of each steel’s most optimal chemical composition and microstructure, providing outstanding combinations of strength, ductility, and cracking resistance. The hulls of Project 955 Borei-class (NATO reporting name Borei) nuclear-powered ballistic missile submarines (SSBNs), a.k.a. Dolgoruky class, were also made of these steels.

-

Note: These steels, with outstanding combinations of strength, ductility, and cracking resistance, are the only advanced steels available today to Russian submarine builders. At present, no research institution/team in Russia has unique and highly sensitive equipment (or a similar one) and is familiar with the experimental approach, which (equipment and approach) were designed/developed by Shipilov in the mid-1980s specifically for this project. For this reason, no new investigation can be conducted in Russia to allow the development of similar or more unique/novel steels for submarine hulls.

-

The yield strength (YS) of the novel steels (1570 MPa) was at least twice as high as the YS of steels (550 MPa for HY-80 and 690 MPa for

HY-100 steel) used by the U.S. Navy for constructing its nuclear submarine hulls. The high YS makes a hull strong enough not to be crushed at depth under hydrostatic pressure. (Although information about the operating depth of submarines is highly classified, their crush depth limits can be approximately estimated based on knowledge of the YS of hull steels.) In addition, subs with a more robust hull are better protected from naval mines. On the other hand, the susceptibility of steels to SCC increases with increasing strength; the hundreds of dives over a submarine’s lifetime mean that resistance to corrosion FCG becomes the most critical issue. Meeting these conflicting requirements—i.e., providing high strength and, at the same time, low resistance to SCC and especially (hydrogen-accelerated) corrosion FCG under cathodic protection—was the most complex part of the entire project, dependent exclusively on Shipilov’s research. In addition, because the content of nickel, a high-cost alloying element, varied from 1% to 4.5% in candidate steels, finding the most appropriate chemical composition was the other difficult task. The steel of choice should have the best possible mechanical properties and cracking resistance and, at the same time, keep the cost of the hull to a minimum. -

The project’s complexity is best seen from the fact that no research organization/team in the United States and Allied nations could develop similar advanced steels for submarine hulls over the last 60+ years. Because of this, the hulls of Virginia- and Columbia-class submarines, “the most advanced and powerful subs” (T. Nilsen, 2020), which are intended to lead the U.S. Navy until the end of the twenty-first century, are constructed of outdated HY-80 and HY-100 steels: the HY-80 steel was first approved for submarine construction in 1955; HY-100 was developed at about the same time.

-

Project 971 submarine K-335 Gepard at the Sevmash shipyard. The vessel’s length is 113.3 m, beam 13.6 m, and draught 9.6 m. Photo: JSC PO Sevmash.

Project 955A submarine K-549 Knyaz Vladimir in the dock at the Sevmash shipyard. The vessel’s length is 170 m, beam 13.5 m, and draught 10 m. Photo: JSC PO Sevmash.

-

Researched SCC and corrosion FCG in titanium alloys designed to replace stainless steel that was highly sensitive to cracking when used as components of steam-generator tubes in the water-cooled (nuclear) reactors of submarines. Consequently, the service life of tubing was expected to increase by 30 times and reach 150,000 hours, equal to the vessel design life.

-

Developed (as a team member) and studied new materials with outstanding combinations of strength, ductility, and cracking resistance for use in aircraft structures, including a titanium alloy for helicopter turbine discs and ultra-high-strength steel for naval aircraft; metal-based composites for nuclear-powered submarines; low-alloy steels with an exceptional combination of strength, ductility, and toughness for drilling equipment; and a biocompatible nickel-free non-magnetic austenitic steel and intentionally corrodible magnesium alloys for medical applications. Research findings on titanium and magnesium alloys for aerospace and naval technology were also used in critical medical device applications, including cardiovascular and orthopedic devices and smart medical systems and technology.

Drill bits for the discovery and extraction of oil and natural gas, including rotary tri-cone drill bits with welded teeth, reinforced centrifugally with polycrystalline diamond inserts.

Advances in Materials Testing and Monitoring Techniques:

-

In 2017, designed, assembled, and adjusted (with C. Brownfield and M. Wimmer) special equipment for in situ monitoring SCC and corrosion FCG in metals with the world’s highest average crack extension resolution of about 10 nm, which is at least 100 times more precise than provided by the best (laboratory) experimental setups of this type in existence; the achieved resolution is 2,500 times more accurate than in commercially available packages.

-

Note: The use of the world’s most advanced crack-monitoring technique is crucial for materials testing to ensure the safety of the current fleet of military aircraft and nuclear-powered aircraft carriers and submarines, which currently serve beyond their initial design life, and water-cooled reactors at hundreds of nuclear power plants worldwide of which operation was, or soon will be, extended to 60 or 80 years. The United States has the largest fleet of reactors in the world. As of May 2021, 88 of America’s 93 reactors have received approval for their first 20-year extension (beyond the initial design life of 40 years); most of these will expire in the 2030s. Utilities are now determining if they should apply for an additional 20 years of service (beyond 60 years). Environment-induced cracking in nuclear reactor cooling systems, reactor internals, and core components is one of the highest priority issues affecting the longevity of these aging reactors.

-

Figure 1. Crack length vs. time for high-strength low-alloy steel in the air. Note: The exceedingly high stability of FCG recording (right) and the possibility of detecting a less than 10 nm crack increment (per cycle) confirm that this is the world’s most sensitive experimental setup for crack growth monitoring. For the first time, this setup allowed monitoring/recording a crack increment per cycle in real-time and drawing the crack growth graphs of each point corresponding to the actual crack increment, measured in situ and operando. The feature makes the graphs substantially different from traditional da/dN-ΔK curves in which crack growth rates are determined based on the cumulative crack advance over dozens, if not hundreds or thousands, of load cycles (i.e., hours and days).

-

In 1984, designed, assembled, and adjusted special equipment for studying SCC and corrosion FCG in metals that allowed in situ and operando detecting as little as 0.001-mm (approx. 1/100th of a razor blade) crack extension and applying an electrochemical potential during crack growth (USSR patent, SU 1413488 A1, 1987, with V.A. Marichev). This was the most sensitive experimental setup of this type for at least a decade.

-

Note: The experimental setup allowed, in 1984, monitoring crack growth 2 to 5 times more accurate than was possible 14 years later, in 1998, at GE Corporate R&D Center and Studsvik AB (Sweden), 5 to 10 times more accurate than at the VTT Technical Research Centre of Finland, 10 to 20 times more accurate than at AEA Tech (successor of the U.K. Atomic Energy Authority), and 20 to 30 times more accurate than at ABB [ASEA Brown Boveri], the world’s leading electrical engineering group committed to nuclear power. The resolution was also ten times higher than available at the Tokyo Institute of Technology’s Precision and Intelligence Laboratory in 1993.

-

-

Modified the unique equipment (see immediately above) so it could also monitor crack growth in a variety of aqueous (ambient as well as high-

temperature and pressure) solutions and associated environments (such as aqueous variations in nuclear and petroleum facilities), H2S-rich environments, high-pressure hydrogen, and high-temperature gases. As well the setup made it possible to measure in-situ crack growth rates at an average of 20 nm/min (0.001 mm/h) at temperatures ranging from 4 °C (seawater) to about 300 °C (nuclear reactor operating temperatures) and 500 °C in supercritical water systems. With this setup, it also became possible to monitor crack growth rates in irradiated pressure vessel steels exposed to various mechanical loading conditions.

-

Devised an electrical contact resistance method for in situ investigations of metal surfaces in electrolytes (with V.A. Marichev and V.V. Lunin). With this method, it was possible, for the very first time, to measure the electrical contact resistance of surface films during adsorption of water and anions, to study the kinetics of formation/destruction of hydride and oxide films and the effects of applied potential, activators, and inhibitors on these processes.

-

Developed several novel experimental methods, including a method for accelerated durability in vivo testing of medical implants; a technique for definite initiation of the localized breakdown of oxide films and metallic and non-metallic coatings on metals; a method for conducting in situ and operando electrochemical tests of metallic protective coatings, e.g., in soil or natural seawater (with F. Friedersdorf); and two methods for conducting accelerated laboratory corrosion tests of metals, non-metals (e.g., PVC), and coatings in highly- and severely-corrosive soils (one of the methods with J.W. Moon). Each of these methods is the first of its kind and is patentable.

Important Industrial Problems Studied and Solved (partial list):

-

First determined the cause of the stealth coating falling off the U.S. Navy’s newest Virginia-class nuclear-powered fast attack submarines, which made the submarines more vulnerable to detection.

-

Recognized the necessity of, and advocated for, the correlation of plant and laboratory data in nuclear reactor systems (specifically in VVER-1000 pressurized water reactors) derived from using electrochemical and fracture-mechanics experimental methods. Such correlated data was used between 1992 and 1994 to identify the mechanism and solve the problem of SCC in VVER-1000 steam-generator collectors that appeared after 7,000-59,100 hours (0.8-6.8 years) of operation (instead of the usual 240,000 hours). Before Shipilov’s intervention (July 1991), the problem had resulted in the early replacement of 34 steam generators at the cost of 5.54 billion Rubles (U.S.$8.5 billion) between 1986 and 1991.

-

Note: It is the only (safety-critical and widespread) SCC problem that has been successfully solved in commercial nuclear power since the mid-1950s. (In the mid-1950s, the most perspective sodium-cooled S2G reactor experiencing SCC problems was removed from the perspective sodium-cooled S2G reactor experiencing SCC problems was

-

VVER-1000 horizontal steam generator. The vessel’s length is 15.6 m, and its diameter is 4.8 m. (Note: An individual’s head in the bottom left corner can give a sense of the steam generator’s size.)

removed from the world’s second nuclear-powered submarine USS Seawolf (SSN 575); it was replaced with the less-efficient water-cooled S2Wa reactor. Without a doubt—as acknowledged by Admiral H.G. Rickover, the “father of the nuclear navy,” in his statement before the U.S. House and Senate Joint Committee on Atomic Energy in March 1957—SCC was one of the major restrictive factors in creating more efficient marine propulsion (and later also commercial nuclear reactors) than those currently in use. The inability of the corrosion research community to solve the problem of SCC of austenitic stainless steel in the mid-1950s predetermined all future development of nuclear power, which could be more efficient otherwise.)

-

Identified in 1993 and advocated for recognizing the dominant role of hydrogen embrittlement and service pressure fluctuations in the service failures (ruptures) of cathodically protected underground pipelines. Consequently, a decade later, most laboratories worldwide followed Shipilov by re-orienting their research from static SCC and “anodic path dissolution,” of which the idea was proposed decades earlier based on the lack of knowledge about SCC mechanism, to HIC and corrosion FCG; this has benefited the global oil and gas pipeline industry.

-

Assessed the role of cathodic protection in oil and natural gas pipeline safety and reliability and showed that the practice of cathodic protection raises questions that indicate that it is necessary to reassess this current method of preventing corrosion in pipelines.

-

Conducted (as a principal investigator) a nationwide study aimed at determining the correlation between soil chemistry and the occurrence of pipeline SCC, which was part of the Russian-Ukrainian R&D Program “Highly Reliable Pipeline Transport,” which was signed by Russian prime minister Victor S. Chernomyrdin and Ukrainian prime minister Leonid D. Kuchma; the Interstate Program was chaired by Boris E. Paton, President of the National Academy of Sciences of Ukraine. Although no apparent correlation was found, it was revealed that cathodic protection and sulfate-reducing bacteria worked together to promote SCC. It was also revealed that hydrogen charging, embrittlement of steels, and hydrogen-accelerated microstructural changes in steels resulted in the significant loss of steel resistance to SCC even within the expected life span of oil and gas pipelines.

-

In 1993, Shipilov first predicted that with increasing the diameter of a pipe, the average operating time of a pipeline before its rupture due to SCC should decrease while the length of the ruptured zone should increase; in 1995, the trend was confirmed by statistics on natural gas pipelines by Vadim Polyakov.

Figure 2. Effect of pipe diameter on fracture/rupture time and the length of a fractured zone for large-diameter natural gas pipelines (V.N. Polyakov, 1995). Note: Figure 2 shows that increasing the diameter of a pipe from 720 mm (28 in) to 1,420 mm (56 in) results in decreasing the average operating time of a pipeline before its (possible) rupture from 18 to six years; at the same time, the length of a ruptured zone increases from 23 m (76 ft) to 81 m (266 ft). In addition, it is known that increasing yield strength accelerates crack growth, and it is a typical pattern that materials, which have higher strength, are among the most prone to SCC, corrosion fatigue, and hydrogen embrittlement. Despite the above facts, recent trends in the pipeline industry in Canada and the United States include using stronger steels having yield strength in the range 690–830 MPa (100–120 ksi); using more negative potentials of cathodic protection (e.g., –1.2 V, with permissible excursions to –1.5 V vs. CSE), known to be one of the significant contributors to pipeline SCC; and using larger diameter pipes (e.g., 1,070 mm [42 in]) in newly constructed pipelines. A fact that can be stated with certainty today is that these trends, used separately, all together, or in any two combinations, will result in a significant

acceleration in SCC-related failures; some of the failures would cost pipeline owners $1 billion to $2 billion.

Most Important Expertise Contributions:

-

In 2020, first assessed the impact of materials deterioration and corrosion on the U.S. Navy combat readiness, with a focus on Navy and Marine Corps aircraft for the National Commission on Military Aviation Safety, which was created by Congress in 2019 out of concern for the recent increase in military aviation accidents.

-

Note: While the Commission found that “military aviation losses from 2013 through 2020 cost the lives of 224 pilots and crew members, 186 aircraft, and $11.6 billion in damages,” Shipilov demonstrated that corrosion, being the main driver of the Navy’s reduced readiness, poses numerous safety risks and is a significant concern to naval aircraft operating in the highly corrosive marine environment, affecting nearly all common structural materials to some extent.

-

-

Served as one among three NACE International Expert Panelists invited “to answer a series of questions on the combined causes of SCC, the technologies needed to detect and address this form of corrosion, and unfolding developments to improve the performance and safety of pipelines susceptible to SCC.”

-

Developed, at the request of Rep. Jim Oberstar, Chairman of the U.S. House Committee on Transportation and Infrastructure from 2007 to 2011, the concept of the Sustainable Infrastructure R&D Initiative of the United States (SIRIUS) aimed at structuring the efforts of top research universities, national laboratories, and various agencies to address the areas of critical needs as regards to the nation’s core (and crumbling) infrastructure. Shipilov had several meetings with U.S. lawmakers and mayors, a meeting with Associate Director for Science at the White House Office of Science and Technology Policy Carl Wieman in October 2011, and was invited to Capitol Hill in February 2013 to discuss SIRIUS. In September 2017, he introduced SIRIUS to Vice Chairman of the House Transportation and Infrastructure Committee Rep. John Duncan, Jr.

-

Developed a variant of SIRIUS, entitled “Sustainable Infrastructure R&D Initiative: Utilities and Structures,” focusing on Canada’s critical infrastructure, which was recommended for realization in the province of Ontario by Minister of Research, Innovation and Science of Ontario Reza Moridi, MPP.

-

In 2009, Shipilov provided the first estimate of corrosion's impact on the Canadian economy based on existing evidence. The estimate, being “certainly the best exposition of the problem of corrosion cost” (Roger Staehle), is intended to play a vital role in stimulating the development of national strategies and corrosion R&D programs for minimizing corrosion-related losses in the country. (Note: His estimate became an essential source for the 2021 IMPACT Canada Study, which “provides a means for government and industry to coordinate on best practices for corrosion management and planning in diverse industry and municipal sectors.”)

-

In 1995, initiated discussion of and argued for the importance of integrating scientific, engineering, economic, and environmental concerns when researching the environment-induced cracking of materials that he demonstrated (based on his and others’ findings and consulting experience) is the most common cause of mechanical failures in a wide variety of industries.

-

In 2011, first demonstrated that metal fatigue—which is widely cited as being responsible for 90% of all mechanical failures and toward which about $2 billion (in 2020 dollars) in testing and research is spent each year in the U.S. alone and twice more worldwide—is, in fact, responsible for only a few percent of mechanical service failures.

-

At the request of the U.S. Department of Defense (DoD) Office of Corrosion Policy and Oversight developed the concept of the Defense Institute for the Science and Technology of Corrosion (DISC) “to accelerate discovery and deployment in the field of corrosion and corrosion control to meet 21st-century defense needs by increasing the efficiency of known corrosion control technologies and developing new material solutions for use in specific military applications and extreme environments.” (Note: The concept of DISC was developed to help the DoD in preventing and mitigating the corrosion of the military equipment and infrastructure, which costs the U.S. Armed Forces over $20 billion a year and is “potentially the number one cost driver in life-cycle costs” in all military services.”)

-

At the request of the U.S. Senate Appropriations Subcommittee on Energy and Water Development, Shipilov developed a project entitled “Evaluation of Zinc-Coated Ductile Iron Pipe in Highly- and Severely-Corrosive Soils,” in which the U.S. Bureau of Reclamation, a federal agency under the U.S. Department of the Interior, invested $1 million (for the first year). In August 2016, the project—which intended to use novel (electrochemical and microbiological) experimental methods and the advantages offered by World STAMP (World Spatiotemporal Analytics and Mapping Project) to identify trends, patterns, anomalies, and changes in the corrosion behavior of more than 36,500 pipe specimens made of 333 varieties of ferrous, nonferrous, and protective coating materials and exposed to 95 soils and 128 sites across the United States to build anticipatory algorithms that would evaluate future scenarios and outcomes—was described as “the most comprehensive study in the field of the external (soil-side) corrosion of water mains to date” by Gregg Horn, Vice President of the Ductile Iron Pipe Research Association (DIPRA), which represents all the ductile iron pressure pipe manufacturers in North America and that has been involved in similar research since 1928.

-

Note: The second part of the multidisciplinary and interinstitutional study, entitled “Drinking Water Infrastructure Protection and Lifetime Prediction: Water Supply Distribution Systems,” aimed to reduce the impact that corrosion—with the annual direct cost of more than $70 billion—has on the U.S. water and wastewater systems.

-

External localized corrosion of an 8-in. ductile iron pipe in the soil after 2.5 years in service.

-

In mid-2007, recommended—based on available information and the lack of the necessary expertise in the field of nuclear corrosion science in Canada, resulting, among other problems, in excessive corrosion of outlet feeder pipes carrying the coolant from reactor cores to steam generators at all CANDU pressurized heavy water reactors—to make (better immediately) the residual-life assessment of the pressure vessel, internals, and core components of the 50-year-old National Research Universal (NRU) reactor (S.A. Shipilov, “Technological and Environmental Innovation: Support for Industry, Advanced Education, and Sustainable Development,” paper presented at a meeting organized by the National Research Council (NRC) of Canada, July 5, 2007).

-

Note: In May 2009, shortly after Shipilov’s repeated warnings were ignored by the NRC’s leadership of that time, the NRU reactor shut down automatically because of the heavy water leak caused by corrosion in the reactor vessel wall; this was the second leak since late 2008 when heavy water containing tritium leaked from the reactor, but the leak stopped before the source could be identified.

-

The NRU reactor produced more than half of the world’s supply of medical isotopes used to diagnose cancer and other illnesses, i.e., more than any similar facility in the world. The shutdown occurred when only one of the other four regular medical isotope reactors in the world was in service, resulting in a worldwide shortage of radioisotopes for medical treatments. Initially supposed to last a month, the outage lasted 15 months, compromising Canada’s future role in the field. Atomic Energy of Canada Ltd. (AECL) estimated the cost to get the reactors operating properly would be at least $1 billion. In March 2018, the NRU reactor was permanently shut down ahead of decommissioning, initially scheduled for 2028.

-

The other stunning outcome of the decision to keep NRC away from involvement in extensive and well-organized corrosion-related research, including research for the Department of National Defence (DND), as also proposed by Shipilov in July 2007 (and multiple times before and afterward), is the restriction for the Royal Canadian Navy’s four Victoria-class submarines to “dive deep beneath the seas because of rust damage to the hulls.” For example, it was revealed that the hull of HMCS Chicoutimi (SSK 879) “corroded beyond its safe operating limit. In addition, … the hull valves were cracked;” according to the Navy, “repairing seven areas of general rust and three regions of localized pitting rust on HMCS Windsor [SSK 877] … would cost between $3 million to $5 million and take a year to do.” In 2019, Canada’s submarines “spent zero days at sea” though, according to DND, “Canada’s submarine force provides a key strategic asset with formidable surveillance and intelligence gathering capabilities, as well as the ability to control or deny access to a substantial ocean or littoral area.” In June 2021, HMCS Corner Brook (SSK 878) “went back in the water” for the first time in 10 years.

-

-

At the Russian Government’s request, served as a principal expert and/or technical consultant on several high-profile accident investigations, including the analysis of a sunken nuclear-powered submarine K-278 Komsomolets in 1992 (after its wreck was explored and filmed by Mir-1 and Mir-2 submersibles in 1991 and 1992) and the major oil spill from a corroded pipeline in Russia’s Komi Republic in 1994:

-

Note: The K-278 Komsomolets, an experimental titanium-hulled submarine and the only submarine of the Project 685 Plavnik (NATO reporting name Mike), sank in the Norwegian Sea in 1989, taking the lives of 42 sailors, The wreck currently lies at a depth of 1,658 m

with a nuclear reactor and two torpedoes tipped with nuclear warheads, each containing about 3 kg of plutonium-239; in the

1990s, in some quarters, the wreck was regarded as a potential underwater Chornobyl because of the deterioration and corrosion of the submarine’s materials. Although Shipilov’s conclusions made in June 1992 contradicted those of other leading experts in the country, at least two of his recommendations—sealing all hull cracks (which he showed were not caused by/related to SCC as was thought) and covering the nuclear warheads—were implemented in part in July 1995 after a plutonium leakage was revealed from one of two nuclear torpedoes in mid-1994. It allowed the Government to declare in 1996 that “the risk of radioactive contamination of the environment is negligible until 2015 or 2025.” -

The oil spill from a severely corroded pipeline in Komi was the third largest release of oil into the environment on record. Its aftermath was investigated by two U.S. Senate Committees in 1995.

-

The wreck of the Komsomolets at the bottom of the Norwegian Sea on July 7, 2019. Photo: Institute of Marine Research/G.O. Sars and University of Bergen/Ægir 6000.

One of the worst oil spills in modern history, when the aging pipeline network in the northern Komi Republic sprang a series of leaks in August 1994. Photo: Roman Polshvedkin.

-

Served as a national coordinator for an interinstitutional and multidisciplinary R&D project on environment-induced cracking in Russia at the request of Anatoly P. Aleksandrov, president of the USSR Academy of Sciences from 1975-1986, that aimed to prevent structural failures in

high-risk and safety-critical technologies.

Other Notable (Industrial) Problem Solving Work:

-

Provided the estimate of the FCG resistance and assessed the residual life of critical structural components of the 668 m (2,190 ft) long suspension Krymsky Bridge over the Moskva River, the most vital bridge in the Moscow transit system. (Note: Completed in 1938, the six-line bridge carries an average of 150,000 vehicles per day or 55 million per year.) Shipilov’s estimate resulted in the partial closure of and extensive repairs to the bridge (including replacing the bridge deck) from April to December 2001.

-

Shipilov’s evaluation of the 19th-century 280-m (920-ft) long Canadian Pacific (CP) Railway trestle bridge at mile 203.46 of the Belleville Subdivision—which stretches about 60 m (196 ft) above the East Don River and East Don Trail and 50 m (164 ft) above the Richmond Hill GO Transit and VIA Rail line—and two 75-m (250-ft) and 60-m (200-ft) long Canadian National (CN) Railway bridges at miles 8.5 and 8.8 of the Bala Subdivision over the East Don River in Toronto between 2012 and 2014, resulted in the beginning of extensive multi-million-dollar repairs to the bridges at the request of the Minister of Transport Canada in 2015. Before that, in May 2014, following Shipilov’s work, Toronto City Council requested that copies of all structural safety reports for each CP bridge within the City’s boundaries be released. In addition, in June 2014, City Council formed a working group on “Dangerous Railway Cargo and Measures to Improve Community Safety” and asked CP and CN Railways to provide City Council with State of Good Repair information on all their infrastructure within the City of Toronto.

The Krymsky Bridge over the Moskva River in Moscow, Russia. Photo: A. Savin.

The CP Rail trestle bridge over the East Don River and East Don Trail in Toronto, Ontario. GO Transit and VIA Rail passenger trains pass daily under the trestle.